The minimal installation effort combined with the high level of safety provided by the integrated contact protection make the CrossBoard ® from Wöhner the ideal system solution for power distribution systems. Previously known for power distribution systems up to 160 A, the system world has now been extended to 800 A, which means that almost the entire spectrum of applications, from control and automation technology to large power distribution systems, can now be covered. Thanks to the innovative hybrid rail, components with the patented plug-in contacting up to 160 A, but also outgoing circuits higher than 160 A with the proven terminal contacting can be mounted on the same basic system without additional adapters.

The consistent front and rear contact protection to IP20 offers a high degree of safety, which enables the creation of a power distribution system in accordance with the DIN EN IEC 61439 and UL 508 standards. If required, it is possible to upgrade to IP40.

A key aspect of product development at Wöhner is the focus on global application. Our out-of-the-box systems fulfil the globally relevant IEC, UL and CCC certifications in one and the same product, which makes it very convenient and easy for the user. One standard, applicable everywhere.

The CrossBoard® is a pre-assembled out-of-the-box system that saves users a lot of time during assembly: simply unpack, assemble in one step and immediately start plugging or snapping on the components without tools.

Maximum simplicity throughout the entire life cycle, from planning to installation and maintenance. Just one article number for an entire busbar system, no need for short-circuit calculation, virtually no assembly work when installing the system and standard tool-free assembly of the components simplify wherever possible.

Compatibility is one of the key aspects that make the CrossBoard system world what it is. A global standard. CrossBoard products can also be used on other base systems without any problems via adaptation solutions. The hybrid rail now merges two worlds, the world of plug contacting with the world of terminal contacting, providing the user with a broad portfolio of assembly components.

Our out-of-the-box systems are designed to safely conduct and distribute current in a minimum of installation space. The basic variants of the CrossBoard with 160 A rated current, perfect for applications in control and automation technology, are designed for a compact 160 mm height. Familiar from the 60 mm system technology 60Classic and due to the compatibility of the system worlds, the CrossBoard with 800 A rated current grows to a height of 200 mm. The widths of the out-of-the-box systems are based on the standard control cabinet widths, which means that distribution boards up to 1100 mm wide can be mapped as standard.

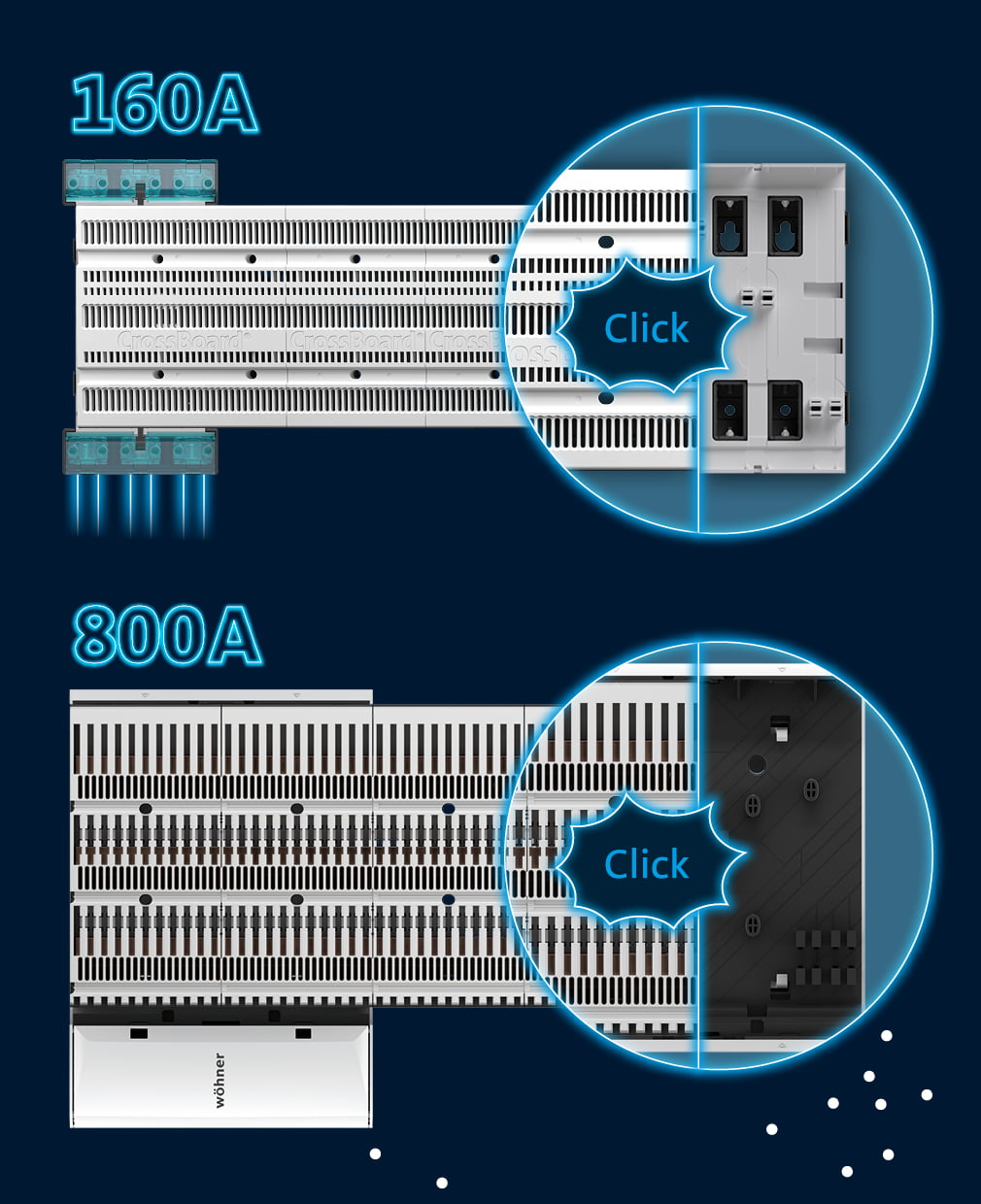

Our contacting is also standardised. Up to 160 A, the patented plug contact is preferably used; above 160 A, the surface-mounted components are fitted with the clamping bracket known for its robustness. Of course, exceptions prove the rule here too.

In our eyes, a solution can only become a standard if it is open rather than proprietary. This is exactly the approach we are taking with the CrossBoard interface by opening the interface to components from other manufacturers and supporting third parties in the development of add-on components.

The CrossBoard system world comprises three generations with different application focusses.

System height: 160 mm

Rated current: 125 A (IEC) / 100 A (UL)

Assembly: Direct mounting on DIN mounting rail or mounting plate

Contacting: Plug-in contacting of surface-mounted components

2 widths: 225 mm & 405 mm

System height: 160 mm

Rated current: 160 A (IEC/UL)

Assembly: Plug-and-play assembly with rear feed up to 320 A

Contacting: Plug-in contacting of surface-mounted components

9 widths: 300 mm – 1100 mm

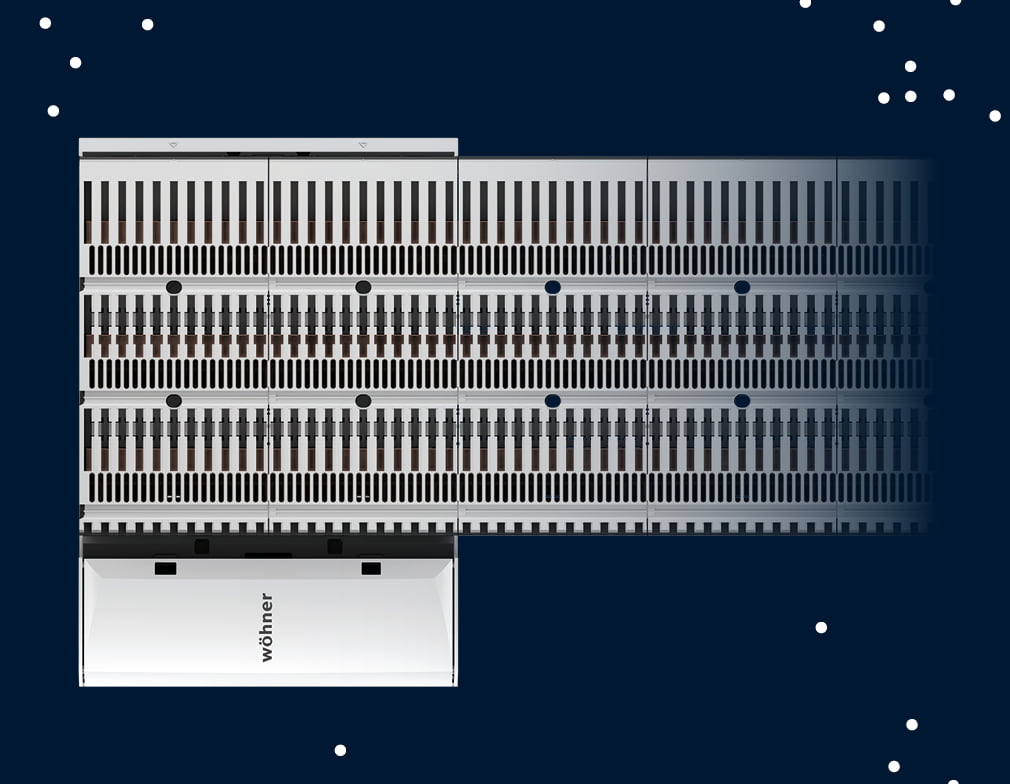

System height: 200 mm

Rated current: 800 A (IEC/UL)

Assembly: Plug-and-play assembly with rear feed up to 800 A

Contacting: Plug-in contacting & terminal contacting of surface-mounted components using hybrid rails

7 widths: 500 mm – 1100 mm

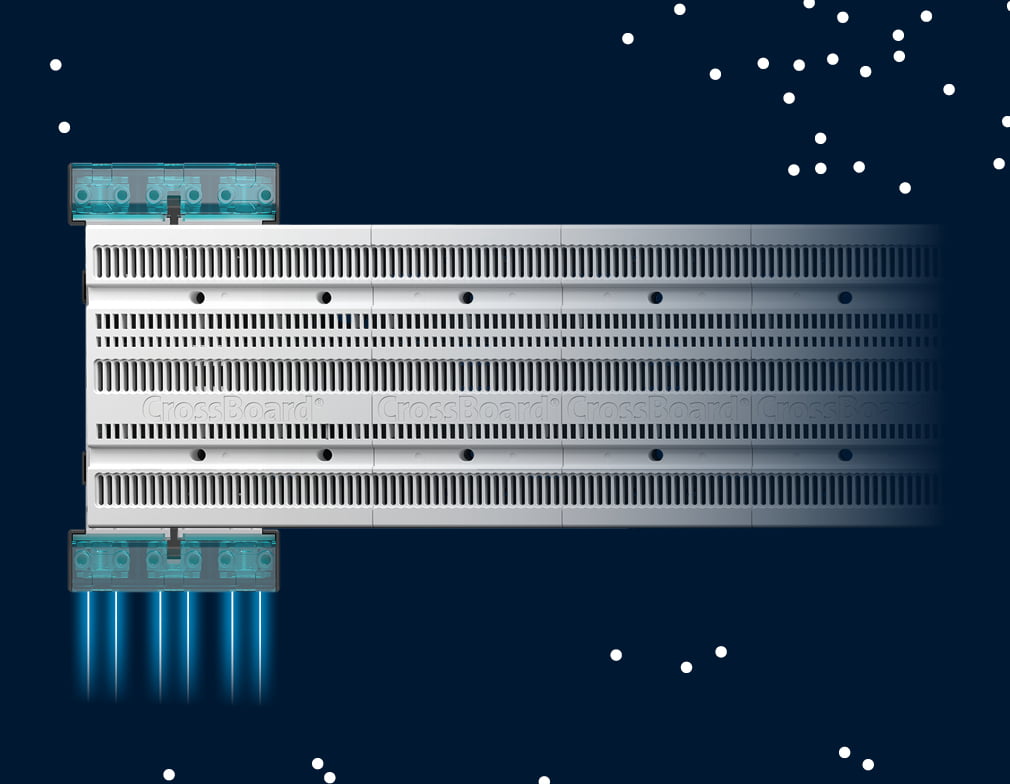

Installation is even easier with the CRITO® power feed and mounting modules on the rear. With these, the CrossBoard can be electrically contacted and mechanically fixed in just one step – real plug & play. This installation and feed-in method, which is unique on the market, is possible for both the 160 A and 800 A versions of the CrossBoard®.

In addition to the significantly faster installation, this type of mounting and feed has another significant advantage – saving space on the front. Space that was previously required for an feed is now available again and can be used for any outlets. With an feed-in power of 800 A, up to 160 mm of additional space is generated at the front, which means that the entire width of the busbar system and therefore, at best, the control cabinet can be reduced. Real sustainability by saving resources.

In addition, all variants can also be easily screwed onto the mounting plate using the screw holes provided.

The busbar is without doubt the central element of a busbar system. That is why this element has been given special importance in the latest generation of CrossBoard®. The new hybrid rail contains a total of three functional interfaces and is fully in line with the Wöhner philosophy.

On the outgoing side, the patented and simple plug-in contacting is used for contacting up to 160 A. An interface for robust terminal contacting is available for outgoing circuits above 160 A. A solid interface is available for the rear feed in order to bring the full power of 800 A to the system.

This means that the hybrid rail is not just a simple busbar, but connects the system worlds and allows them to merge. This means that large power outgoing feeders, familiar from the 60Classic world, can now be easily combined with small outgoing feeders for motor starters, switches or power supply units without the need for additional adapters.

The new hybrid rail is also a real pioneer in terms of sustainability, as the unusual design can save up to 40 % copper for a comparable application.